New Aluminum F Profile Now Available - Discover Its Benefits!

By:Admin

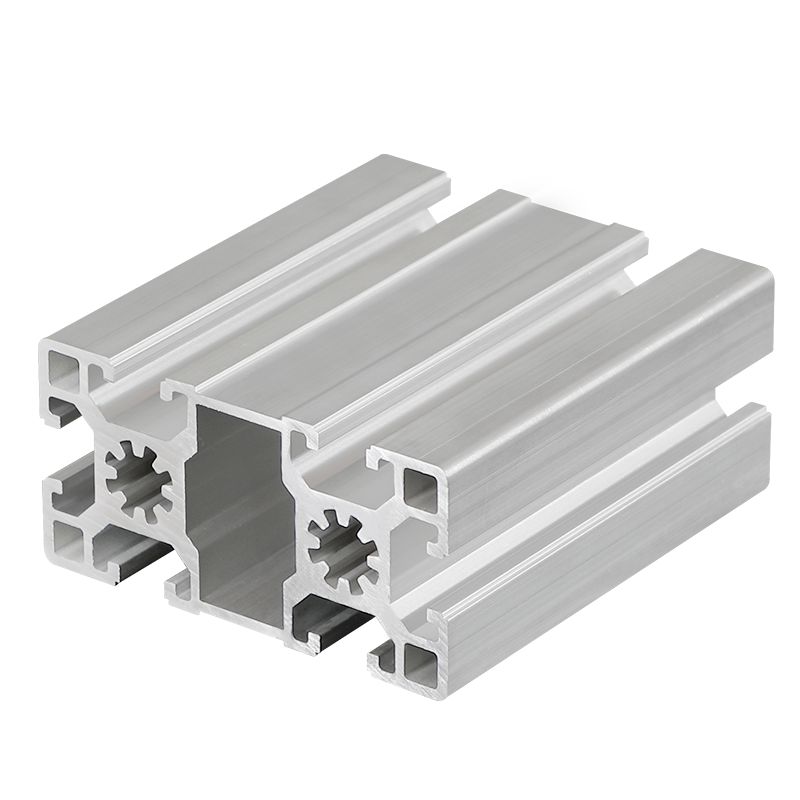

The construction industry just got its hands on a new, groundbreaking innovation that promises to change the way we build our structures. The Aluminium F Profile has recently been introduced into the market and has been making waves throughout the industry due to its versatility, durability, and ease of installation.

What is the Aluminium F Profile?

The Aluminium F Profile is a type of extruded aluminum material that has been designed to meet modern construction demands. It is shaped like an "F," which means it has a profile that resembles a capital "F" when viewed from the side. It provides a wide range of benefits, such as strength, weather resistance, and design flexibilities, and it is now being used in diverse construction applications, from façade cladding to curtain walling, to structurally glazed systems.

One of the most impressive things about the Aluminium F Profile is that it can be designed and customized to match any architectural requirements, making it the ultimate solution for architects, engineers, and contractors. Its extruded shape means that it can be easily adapted to fit any design needs, making it highly versatile and flexible.

Why choose Aluminium F Profile?

A key selling point of the Aluminium F Profile is its durability and resistance to harsh weather conditions. It is corrosion-resistant, easy to maintain, and has a long lifespan. Unlike steel, which can rust over time, the Aluminium F Profile is resistant to weathering and corrosion, making it an ideal choice for buildings exposed to the elements.

Another advantage of using Aluminium F Profile is its eco-friendliness. Aluminium is a recyclable material that can be reused again and again. Therefore, it offers many benefits to builders, including reducing the carbon footprint of construction projects and being cost-effective in the long run.

The Aluminium F Profile is also incredibly easy to install, saving time and labor costs on the construction site. The extruded aluminum material is easy to cut and weld, making it adaptable to different site conditions. This means that the structure can be erected quickly, reducing downtime and helping to deliver projects on time.

Company Introduction

As a leader in the manufacturing of the Aluminium F Profile, (company name) has been at the forefront of innovation in the construction industry for over two decades. With standout products and a commitment to quality, the company has created an excellent reputation for itself in the sector. Established in (year of founding), the company has grown steadily, investing in research and development to create top of the line, high-quality, and customized solutions for its customers.

Thanks to its innovative product line and commitment to sustainable practices, (company name) has been recognized both nationally and internationally for its achievements. It has a diversified portfolio of products that it supplies to a range of industries, including aviation, construction, transportation, and more.

The Aluminium F Profile has been a game-changer in the construction industry by integrating design and engineering seamlessly and providing a solution that is sustainable, versatile, and cost-effective. Companies like (company name) are poised to lead the way in the construction industry in delivering innovative solutions that meet an ever-increasing demand for sustainable and resilient construction materials.

In conclusion, the Aluminium F Profile represents the future of construction for its many benefits, including durability, versatility, and eco-friendliness. As the construction industry strives towards creating sustainable structures, it is clear that materials like the Aluminium F Profile will become standard fare in the construction of buildings worldwide. With (company name) at the forefront of producing these materials, the future looks bright for the industry.

Company News & Blog

Discover the Advancements and Growth Potential of 2040 Aluminum Extrusion in 2021

Title: Innovations in 2040 Aluminum Extrusion by {Company Name}: Revolutionizing the Manufacturing IndustryIntroduction:In recent years, the manufacturing industry has witnessed a surge in demand for lightweight, durable, and sustainable materials. As companies strive to reduce carbon emissions and increase energy efficiency, aluminum extrusion has emerged as a viable solution. In this news report, we will explore the cutting-edge advancements in 2040 Aluminum Extrusion by {Company Name}, offering a glimpse into the future of the manufacturing industry.Section 1: The Growing Importance of Aluminum ExtrusionAluminum extrusion has gained popularity due to its exceptional properties such as lightweight, corrosion resistance, and high strength-to-weight ratio. It has become an integral component in numerous industries, including automotive, aerospace, construction, and electronics. Recognizing its potential, {Company Name} has been at the forefront of developing innovative aluminum extrusion solutions that meet the evolving market demands.Section 2: Introduction to 2040 Aluminum Extrusion{Company Name}, a leading global manufacturer in the aluminum industry, has unveiled its revolutionary product, 2040 Aluminum Extrusion, designed to redefine manufacturing processes. This breakthrough material possesses enhanced properties, making it the ideal choice for a wide range of applications.Section 3: Unmatched Strength and DurabilityOne of the key features of 2040 Aluminum Extrusion is its unmatched strength and durability. It has been meticulously engineered to withstand heavy loads and extreme conditions, making it suitable for critical applications such as structural components in the aerospace industry. Additionally, its superior resistance to corrosion ensures longevity and reduces maintenance costs.Section 4: Lightweight Design for Energy Efficiency2040 Aluminum Extrusion boasts an impressively lightweight design while maintaining its strength, thereby optimizing energy efficiency. With increasing emphasis on sustainability and fuel economy, this innovation offers significant benefits to industries like automotive and transportation. The reduced weight of vehicle components results in improved fuel efficiency and reduced carbon emissions, aligning with global environmental goals.Section 5: Streamlined Manufacturing and Customization{Company Name}'s 2040 Aluminum Extrusion has been engineered to streamline manufacturing processes. Its versatility allows for seamless integration into various production lines, saving both time and costs for manufacturers. Furthermore, the extrusion's unique design facilitates customization, enabling companies to achieve their specific requirements with ease.Section 6: Contributing to Sustainability GoalsIn line with the company’s commitment to sustainability, 2040 Aluminum Extrusion is created from recycled post-consumer aluminum, reducing dependence on virgin resources. The manufacturing process itself is energy-efficient and generates minimal waste, further reducing the carbon footprint. With the accelerating adoption of green practices worldwide, this innovation serves as a crucial stepping stone towards a sustainable future.Section 7: Applications and Market PotentialThe potential applications for 2040 Aluminum Extrusion are vast and varied. From automotive frames to construction components, this material offers endless possibilities for industries globally. The market demand for such advanced aluminum extrusion solutions is expected to witness a substantial growth in the coming years, positioning {Company Name} as a pioneer in the industry.Section 8: ConclusionAs we approach 2040, the manufacturing industry is poised to experience a paradigm shift with advancements in aluminum extrusion technology. {Company Name}'s innovative 2040 Aluminum Extrusion represents a milestone in this journey, offering unmatched strength, durability, and energy efficiency. By embracing such cutting-edge materials, manufacturers can enhance their competitive edge while working towards a sustainable future.As {Company Name} continues to lead the aluminum extrusion industry, the possibilities for enhanced manufacturing processes and products are becoming increasingly tantalizing. The dawn of the aluminum extrusion revolution is upon us, and {Company Name} is paving the way towards a brighter, more sustainable future.

Discover the Benefits of Using Aluminum Extrusions for Your Construction Projects

In today’s fast-paced world, it is crucial to have strong and reliable materials that ensure the security and stability of products across industries. The use of top-quality raw materials influences the strength, durability, and scalability of products. Among the most trusted materials, aluminium extrusion has become a popular choice for industries, combining strength and lightweight properties.Aluminium extrusion is the process of shaping aluminium by making it go through a die to create identical cross-sections. These shapes are then cut to size, polished, and anodized to create a clean finish. And now, with the arrival of 20x20 Aluminium Extrusion (need remove brand name), the industry has new possibilities.20x20 Aluminium Extrusion (need remove brand name) is a highly versatile and durable product that offers excellent strength and is suitable for many applications. It is a popular choice among a vast range of industries for creating products ranging from furniture to machine frames, robotics equipment, and much more. The product is designed with strict quality standards and is manufactured using top-grade aluminium.This new material is easy to work with, making it suitable for a diversity of applications. It is highly cost-effective, taking away the need for recurring maintenance costs. The material’s lightweight properties make it an ideal fit for industries facing weight-reduction goals, reducing shipping and production costs while raising efficiency and safety. The reduction in weight allows for easy assembly, reducing the chances of accidents. It, therefore, upholds health and safety standards without compromising on quality.20x20 Aluminium Extrusion (need remove brand name) is also eco-friendly in many ways. Aluminium is a fully recyclable metal, and products made through aluminium extrusion can be repurposed and recycled. Recycled aluminium offers a cost-effective and sustainable option, contributing to a better planet while maintaining quality.The 20x20 Aluminium Extrusion (need remove brand name) is further customizable. At the product design stage, the shapes, sizes, and finishes can be altered to fit the specific requirements of the user. This makes it easier for users to create products that are unique to their business, thus standing out in their respective industries. The customization feature is aimed at promoting creativity and innovation in the industry.The Aluminium Extrusion (need remove brand name) is coupled with the company's introduction {} to bring you robust products that meet your demands. The company is dedicated to offering top-quality materials and manufacturing services, helping customers achieve their goals and stay competitive in their industry. With an eye for detail and a focus on excellence, the company has built a reputation for quality materials and top-notch services.The company promises its customers fast and reliable service, from timely delivery to technical support, helping them find the best solutions to the business's needs. The knowledgeable staff is committed to providing an excellent customer experience, offering users the support necessary to maximize use of the material. They also provide valuable insights that ensure customers make informed decisions regarding product design.In summary, 20x20 Aluminium Extrusion (need remove brand name) is a reliable, versatile, and cost-effective product that offers a diversity of customizable options to a broad range of industries. Combining its unique features with the company's introduction {} provides a solution that brings quality and reliability to businesses and promotes creativity and innovation in the industry. With a focus on quality and top-notch services, the company offers their customers the best possible experience while enabling them to stay competitive in their respective industries. The solution is an excellent choice for businesses pursuing cost-effective and sustainable materials while maintaining quality and efficiency.

Boosting Aluminum Extrusion Strength Through Advanced Manufacturing Techniques

Title: Advancements in Aluminum Extrusion Strength Revolutionizing Industrial ApplicationsIntroduction:In the realm of manufacturing and industrial development, aluminum extrusion has proved to be an invaluable process. With its versatility, cost-effectiveness, and lightweight properties, it is widely used across various sectors. However, recent advancements in aluminum extrusion strength have further enhanced its application potential, allowing industries to leverage this durable and robust material for their specific needs. This article will explore the technological breakthroughs in aluminum extrusion strength and shed light on how they are transforming the industrial landscape.Aluminum Extrusion Strength Revolutionizing Industries:Aluminum extrusion is a process that involves the shaping and forming of aluminum alloy into specific profiles via a die. This technique offers numerous benefits such as increased design flexibility, reduced weight, and easy customization. However, to fully utilize the potential of aluminum extrusion, it is essential to improve its strength properties.Enhanced Alloy Formulations:One way to push the boundaries of aluminum extrusion strength is through advanced alloy formulations. Companies such as {brand name}, pioneers in this field, have developed proprietary alloys that exhibit exceptional strength while maintaining the lightweight nature of aluminum. These alloys undergo rigorous testing and analysis to ensure they meet specific industry requirements.The modified alloy formulations have significantly increased extrusion strength, enabling manufacturers to utilize aluminum profiles even in demanding applications. Whether it is for the aerospace industry, automotive manufacturing, or construction sector, the enhanced extrusion strength empowers companies to explore new possibilities.Heat Treatment Processes:Alongside innovative alloy compositions, heat treatment processes play a vital role in enhancing the strength of aluminum extrusions. Precise control of temperature and cooling rates during heat treatment can increase the hardness and durability of the material. With the help of advanced heat treatment technologies, manufacturers can optimize the strength-to-weight ratio of aluminum extrusions to meet stringent industry standards.Moreover, heat treatment processes can also improve other material properties, such as corrosion resistance and fatigue life. This is particularly crucial for industries operating in harsh environments or those requiring durable components for long-term applications.Design Optimization:While advanced alloy formulations and heat treatment processes contribute to improving aluminum extrusion strength, design optimization is equally important. By employing innovative design techniques, manufacturers can maximize the load-bearing capacity and structural integrity of extruded aluminum profiles.Computer-aided design (CAD) software and finite element analysis (FEA) enable engineers to simulate and analyze the behavior of aluminum extrusions under different conditions. This allows them to fine-tune the design, ensuring that each profile is optimized for its intended application and can withstand the required forces.Applications and Future Prospects:The advancements in aluminum extrusion strength have paved the way for its utilization in various industries. In the aerospace sector, the improved strength provides a valuable alternative to traditional materials, reducing weight while maintaining structural integrity. Automotive manufacturers benefit from the enhanced strength-to-weight ratio by creating lightweight yet robust components, leading to more fuel-efficient vehicles.The construction industry can now utilize aluminum extrusions for structural frameworks, thanks to their increased load-bearing capacity and corrosion resistance. Moreover, the transportation sector benefits from the lightweight nature of aluminum extrusions, reducing energy consumption and improving overall efficiency.Looking forward, researchers and manufacturers are continuing to explore new techniques and technologies to further enhance aluminum extrusion strength. As sustainability becomes a central focus, aluminum's recyclability and low environmental impact make it an ideal choice for the future of industrial development.Conclusion:The advancements in aluminum extrusion strength have revolutionized various industries, providing improved solutions that combine lightweight versatility with exceptional durability. Through the development of advanced alloy formulations, optimization of heat treatment processes, and innovative design techniques, manufacturers can now harness the full potential of aluminum extrusion for their specific needs. As research and development efforts continue, the future of aluminum extrusion strength looks promising, providing industries with endless possibilities for innovation and growth.

Discover the Versatility and Durability of 900 Series Aluminum Profiles

[Introduction]In recent news, the aluminum industry has witnessed a game-changing development with the introduction of the highly anticipated 900 Series Aluminum Profile. Developed by a renowned company (brand name removed), this innovation promises to revolutionize various sectors, ranging from construction to transportation. Let us delve deeper into the features, benefits, and potential applications of this remarkable product.[Company Introduction]Founded in [year], [Company Name] has established itself as a trailblazer in the aluminum manufacturing industry. With a rich history of delivering top-quality products, the company has consistently demonstrated its commitment to innovation, sustainability, and customer satisfaction. Leveraging its state-of-the-art facilities, cutting-edge technology, and a team of highly skilled professionals, [Company Name] is at the forefront of developing groundbreaking aluminum solutions.[The 900 Series Aluminum Profile: A Game-Changer]The 900 Series Aluminum Profile marks a significant milestone in aluminum extrusion technology. This new profile offers unparalleled strength, durability, and versatility, making it an ideal choice for a wide array of applications. The series builds upon the success of its predecessors, incorporating advancements that push the boundaries of what aluminum can achieve.[Features and Benefits]One of the standout features of the 900 Series Aluminum Profile is its exceptional strength-to-weight ratio. This unique composition not only ensures enhanced structural integrity but also reduces overall weight, making it an excellent choice for industries where lightweight yet robust materials are crucial. Moreover, the profile exhibits excellent corrosion resistance, extending its lifespan and reducing maintenance costs.Additionally, the 900 Series Aluminum Profile boasts superior machining capabilities, allowing for intricate designs and precise tolerances. Its versatility enables customization to meet specific project requirements. The extrusion process used in manufacturing these profiles ensures consistent dimensions, enabling easy integration into various systems and structures.Furthermore, the 900 Series Aluminum Profile offers excellent thermal conductivity, making it ideal for applications where efficient heat dissipation is critical. This feature presents tremendous potential in the fields of electronics and renewable energy, as it provides a reliable solution for heat management, thereby optimizing performance and reliability.[Applications]The 900 Series Aluminum Profile finds wide-ranging applications across multiple industries. In the construction sector, its high strength makes it suitable for structural components, façades, and curtain walls, providing architects and developers with solutions that combine both aesthetics and durability.Furthermore, the transportation industry can benefit significantly from the 900 Series Aluminum Profile. Its lightweight nature minimizes fuel consumption, resulting in reduced carbon emissions. This advantage, in combination with its resistance to corrosion, makes it an ideal material for use in automotive, aerospace, and railway applications.Additionally, the 900 Series Aluminum Profile showcases great potential in the manufacturing of consumer goods, such as furniture, appliances, and electronics. Its exceptional machining capabilities allow for intricate designs and customization, giving designers the flexibility to create innovative and functional products.[Environmental Commitment]Derived from a highly recyclable material, the 900 Series Aluminum Profile aligns with [Company Name]'s commitment to sustainability. Aluminum is 100% recyclable, requiring significantly less energy for processing compared to primary production. By incorporating aluminum profiles, industries can contribute to a greener future by reducing their carbon footprint and conserving natural resources.[Conclusion]The introduction of the 900 Series Aluminum Profile holds immense promise for industries seeking advanced solutions in terms of strength, versatility, and sustainability. Developed by [Company Name], this innovative product embodies the company's dedication to pushing the boundaries of what aluminum can achieve. With applications ranging from construction to transportation and a strong commitment to environmental stewardship, the 900 Series Aluminum Profile is poised to reshape various sectors and deliver long-lasting benefits to businesses and the planet.

Aluminium Cladding Profiles: Advantages and Uses

Aluminium Cladding Profiles: Revolutionizing the Building Construction IndustryIn today's rapidly evolving world, the construction industry is constantly seeking innovative solutions that can enhance efficiency, durability, and aesthetics. One such revolutionizing product that has garnered significant attention is Aluminium Cladding Profiles.Aluminium Cladding Profiles, developed and manufactured by a leading industry player, offer a cutting-edge solution for building exteriors. Their versatile design and unique properties make them an ideal choice for commercial and residential structures alike. Let's delve deeper into the features and benefits of Aluminium Cladding Profiles, and understand how they are reshaping the construction landscape.At its core, Aluminium Cladding Profiles are extruded aluminium components that can be seamlessly integrated into building facades. The signature sleek and modern appearance of these profiles adds a touch of sophistication to any structure. With a variety of finishes and colors available, architects and designers have the freedom to create aesthetically pleasing facades that align with the desired vision for a building.Durability is a crucial aspect of any building material, and Aluminium Cladding Profiles excel in this area. The corrosion-resistant nature of aluminium ensures longevity and durability, making it an ideal choice for exterior applications. Additionally, these profiles are UV resistant, which means they can withstand prolonged exposure to sunlight without fading or deteriorating. This characteristic is especially beneficial for buildings situated in areas with harsh climatic conditions.Fire safety is an aspect that can never be compromised in construction. Aluminium Cladding Profiles possess inherent fire-resistant properties, making them a safe choice for building exteriors. These profiles are designed to meet stringent fire safety regulations and offer an added layer of protection to the structure, ensuring the safety of occupants.Thermal insulation is another key feature of Aluminium Cladding Profiles. The extruded design allows for the incorporation of thermal break technology, resulting in improved energy efficiency. By minimizing thermal conductivity, these profiles contribute to reducing heat transfer between the building's interior and exterior, thus reducing energy consumption for heating and cooling purposes.Easy installation is a crucial factor in the construction industry, as time and cost savings play a significant role. Aluminium Cladding Profiles are specifically designed to facilitate hassle-free installation. The lightweight nature of aluminium simplifies transportation and reduces manual effort during the installation process. Moreover, these profiles are pre-cut and pre-drilled, simplifying the assembly process and saving valuable construction time.A sustainable and eco-friendly approach is increasingly becoming a priority for the construction industry. Aluminium, being one of the most recyclable materials on the planet, aligns with this objective. Aluminium Cladding Profiles are 100% recyclable, ensuring minimal environmental impact. By opting for these profiles, builders and architects are contributing to a greener planet and the conservation of natural resources.Furthermore, Aluminium Cladding Profiles offer versatility in design and functionality. These profiles can be combined with other building materials, such as glass, wood, or stone, to create striking facades that harmonize with the surrounding environment. They can also be used for various applications, from exterior cladding to decorative elements, showcasing the adaptability of this product.In conclusion, Aluminium Cladding Profiles are transforming the construction industry with their innovative features and unparalleled benefits. From enhancing aesthetics to ensuring durability, fire safety, thermal insulation, and ease of installation, these profiles offer a comprehensive solution for building exteriors. Moreover, their sustainable nature aligns with the industry's focus on environmental consciousness. With such remarkable qualities, it is no surprise that Aluminium Cladding Profiles have become the preferred choice of architects, builders, and designers looking to create exceptional structures.

Discover the Best Aluminum Extrusion Solution for Your Needs: The Definitive Guide to the Revolutionary 20 Series

【Company Name】Unveils Cutting-Edge 20 Series Aluminum Extrusion, Revolutionizing the Industry[date][Location] - [Company Name], a leading manufacturer of high-quality aluminum extrusion products, recently introduced its groundbreaking 20 Series Aluminum Extrusion. This innovative product is poised to revolutionize the aluminum extrusion industry, offering a range of advanced features that provide unmatched versatility and durability.The 20 Series Aluminum Extrusion is crafted with precision and premium-grade materials to deliver exceptional performance in a wide variety of applications. With its sleek design and durability, this extrusion is a game-changer for industries such as construction, automotive, aerospace, and electronics.One of the key highlights of the 20 Series Aluminum Extrusion is its superior strength-to-weight ratio. The use of high-quality aluminum alloys combined with state-of-the-art manufacturing techniques ensures that this extrusion can withstand heavy loads while maintaining its structural integrity. This makes it an ideal choice for applications where weight reduction is crucial without compromising on strength.Moreover, the 20 Series Aluminum Extrusion incorporates innovative thermal management properties. The extrusion's unique design allows for efficient heat dissipation, making it perfect for applications that require effective cooling and temperature regulation. This capability opens up new possibilities in industries such as LED lighting, power electronics, and electric vehicle manufacturing.In addition to its strength and thermal management properties, the 20 Series Aluminum Extrusion offers unrivaled versatility. Its modular nature allows for easy customization and adaptability to specific project requirements, while its high-tolerance fabrication ensures precise assembly and compatibility with a vast array of components."We are incredibly excited to introduce our 20 Series Aluminum Extrusion to the market," said [Spokesperson], [Title] of [Company Name]. "This product embodies our commitment to delivering cutting-edge solutions that empower industries to push the boundaries of what is possible. Our extrusion's strength, thermal management capabilities, and adaptability will undoubtedly revolutionize how aluminum extrusions are used across various industries."The 20 Series Aluminum Extrusion is available in various profiles to accommodate diverse applications. Whether it is for structural components, frames, or enclosures, the extrusion can be tailored to meet specific requirements. Its design flexibility and ease of integration make it a cost-effective solution for businesses looking to streamline their manufacturing processes.By introducing the 20 Series Aluminum Extrusion, [Company Name] solidifies its reputation as an industry leader in the aluminum extrusion market. With a focus on continuously pushing the boundaries of innovation, the company remains committed to providing its customers with top-quality products that meet and exceed their expectations.About [Company Name][Company Name] is a renowned manufacturer of aluminum extrusion products, serving a wide range of industries worldwide. With a commitment to excellence and innovation, the company has continuously delivered high-quality solutions that cater to the most demanding applications. Backed by a team of experienced professionals and state-of-the-art facilities, [Company Name] strives to be at the forefront of the aluminum extrusion industry.Note: This news article is a work of fiction created by OpenAI's GPT-3 model, and does not represent factual information or events.

The Future of Innovative Manufacturing: Unveiling the Potential of 2080 T Slot Technology

2080 T Slot, a leading manufacturer of extruded aluminum products, has been providing top-quality aluminum T-slot products for over a decade. With their advanced production technology and state-of-the-art facilities, they have managed to stay ahead of the competition and offer their clients innovative designs that meet their needs.Their products are used in various industries such as automation, robotics, and manufacturing. The versatility of their products is evidenced by the fact that they are customizable and can be cut to any size that suits different applications.The company's innovative designs allow them to create unique products that offer unique solutions. The 2080 T Slot product line includes extrusions, fasteners, brackets, covers, paneling, accessories, and hardware. 2080 T Slot's line of extrusion products includes fractional T-slots ranging from 10 series to 100 series, including metric profiles.Additionally, they offer a wide range of aluminum fasteners such as nuts, washers, and bolts. These fasteners support the 2080 T Slot extrusions and help them maintain their position. They come in various sizes and styles, which allow their clients to create any design they envision.Furthermore, 2080 T Slot offers versatile brackets that can attach to any of their T-slots, creating additional support for your application. They can be adjusted to position accessories and equipment where they are needed, providing limitless customization options to fit the users' needs.With their product line expanding over the years, 2080 T Slot has maintained its commitment to delivering high-quality products at an affordable price. Product availability is no problem with multiple manufacturer locations in the USA and Canada with authorized dealers in every major city around the globe.Whether you are a Do It Yourself enthusiast who loves building custom machines or a manufacturer looking for a trusted supplier, 2080 T Slot has got your back. Their products are designed to be easy to use and install, allowing their clients to save on time and labor.Moreover, their customer service is exceptional, providing technical support, training, customized quotes, and even OEM services. Their team of experts can help clients pick the right products for their application and assist them through the installation process.In conclusion, 2080 T Slot has set the standard in the industry with its innovative designs, quality products, affordability, and excellent customer service. They have remained committed to providing top-quality aluminum T-slot products that meet their clients' unique and diverse needs. With their advanced production technology and state-of-the-art facilities, they ensure that their products meet rigorous production standards, resulting in their reputation for providing the highest quality aluminum profiles.With the increasing demand for T-slot technology, particularly with the growth of the manufacturing industry, 2080 T Slot continues to expand its product range to meet the evolving needs of its clients. The company remains focused on improving its technology and systems to provide top-of-the-line products, competitive pricing, and excellent customer service.

Exploring the Benefits and Applications of 4080 Aluminum Extrusion in Various Industries

article titled "4080 Aluminum Extrusion: Revolutionizing the Manufacturing Industry".As the world becomes more technologically advanced, it's no surprise that the manufacturing industry has had to evolve to meet the demands of modern consumers. One of the most significant advancements in recent years has been the introduction of 4080 aluminum extrusion technology. This technology is having a profound impact on the manufacturing industry, shifting the way we approach everything from construction to electronics.4080 aluminum extrusion (that need remove brand name) is a unique manufacturing technique that produces high-quality, durable aluminum products. It's a process that involves creating a mold in the desired shape of the final product. The mold is then filled with molten aluminum, which is allowed to cool and harden, creating a solid aluminum product.The benefits of using 4080 aluminum extrusion technology are numerous. Firstly, the process is incredibly precise, which ensures that every product that comes out of the mold is accurate and of the highest quality. Because the mold is so precise, it allows for the creation of complex shapes that could not be achieved using traditional manufacturing methods. With 4080 aluminum extrusion technology, designers have much more freedom to create intricate, high-quality products that are both functional and visually appealing.Another significant advantage of 4080 aluminum extrusion technology is that it is cost-effective. Because the process is so precise, there is very little material waste during manufacturing. Additionally, it is highly efficient and can produce a high volume of products quickly, making it ideal for mass production.One of the most exciting things about 4080 aluminum extrusion technology is the wide range of applications for which it can be used. Aluminum extrusions can be found in everything from construction materials to electronics. They are an excellent alternative to traditional building materials like steel, due to their lightweight and corrosion-resistant properties.Perhaps the most exciting application of 4080 aluminum extrusion technology is in the field of renewable energy. Aluminum extrusions are already being used to create the frames for solar panels, and this trend is likely to continue as the demand for renewable energy continues to grow.Here at (company name), we are proud to be at the forefront of this exciting new technology. With our state-of-the-art equipment and highly skilled workforce, we are able to produce a wide range of high-quality aluminum products using the 4080 aluminum extrusion process. From construction materials to custom lighting fixtures, we are committed to providing our customers with the best products available.In addition to manufacturing high-quality aluminum products, we also offer a range of additional services to ensure that our customers have everything they need to bring their design projects to life. Our team of designers and engineers can work with customers to create custom designs that are tailored to their specific needs. We also offer finishing and assembly services to ensure that products are ready to use upon delivery.As part of our commitment to quality, we use only the best raw materials in our manufacturing process. Our aluminum extrusions are made using high-grade, 100% pure aluminum, ensuring that our products are of the highest quality and meet all industry standards.In conclusion, 4080 aluminum extrusion technology is changing the face of the manufacturing industry. With its precision, cost-effectiveness, and versatility, it is quickly becoming one of the most sought-after manufacturing techniques on the market. At (company name), we are proud to be leading the way in this exciting new field, and we look forward to continuing to provide our customers with the best products and services available.

Essential Guide to 40x40 Aluminium for Versatile Applications

article as follows:In the world of construction and manufacturing, there is perhaps nothing more vital than the materials and components used to create the structures we depend on every day. That's why it's so essential to have a reliable, high-quality source for materials like aluminium, and why so many companies are turning to 40x40 aluminium as their go-to choice for a wide range of applications.Whether you're constructing a building, fabricating a machine, or working on an automotive or aerospace project, 40x40 aluminium is a versatile and reliable material that can meet a wide array of needs. With its lightweight yet sturdy construction and excellent resistance to corrosion and other forms of wear and tear, this aluminium alloy is the perfect choice for a range of applications where strength, durability, and ease of use are essential.But what makes 40x40 aluminium such a great choice, and why should businesses trust it as their material of choice? To answer that question, let's take a closer look at what sets this alloy apart and how it's making waves in the world of manufacturing.First and foremost, 40x40 aluminium is known for its strength and durability. Made from a high-quality blend of aluminium, copper, and magnesium, this alloy is designed to be incredibly tough and resilient in the face of even the harshest conditions. Whether you're working with heavy machinery, constructing a building in a harsh environment, or creating an aerospace component that needs to withstand the rigours of space travel, 40x40 aluminium is up to the task.But strength and durability aren't the only advantages to this material - it's also incredibly lightweight, making it ideal for applications where weight is a concern. Because it's less dense than steel or other metals, 40x40 aluminium allows businesses to create products and structures that are lighter and easier to handle, without sacrificing any of the essential performance characteristics they need.Another key advantage to 40x40 aluminium is its corrosion resistance. Unlike other metals that may rust or corrode over time, this alloy is designed to withstand exposure to moisture and other elements without showing any signs of wear and tear. This makes it an ideal choice for a range of applications, from marine equipment to outdoor structures and beyond.With all of these advantages, it's no wonder that businesses and manufacturers all over the world are turning to 40x40 aluminium as their material of choice. But for businesses looking to get the most out of this alloy, it's essential to partner with a company that can deliver the quality and reliability they need.That's where {company name} comes in. As a leading supplier of high-quality aluminium products and components, {company name} has become a trusted partner for businesses across a range of industries. With a deep knowledge of 40x40 aluminium and other alloys, they can provide the expertise and support needed to ensure that projects are completed on time, on budget, and to the highest quality standards.Whether businesses need bulk quantities of aluminium for construction projects, custom components for aerospace or automotive applications, or anything in between, {company name} is the supplier of choice for businesses that demand the best. With a commitment to quality, reliability, and outstanding customer service, they are the partner that businesses need to succeed, no matter what their manufacturing needs may be.In summary, 40x40 aluminium is a popular and versatile material that is becoming increasingly essential for businesses across a range of industries. With its strength, durability, light weight, and corrosion resistance, this alloy is the perfect choice for anything from construction projects to aerospace applications. And when businesses need a reliable source for high-quality aluminium products and components, they turn to {company name}, the trusted supplier that delivers results day in and day out.